Plants for Energy, Processing, and Manufacturing

Why use 3D CAD in the engineering of plants?

- Increase the success rate

- Deliver good tenders

- Submit professionalism to your customers

- Reduce costs

- Detailed bill of materials provides good control over costs

- Obtain good estimates of labor cost

- Effectively obtain quotes for materials and equipment

- Reduce production time with good manufacturing drawings

- Enables pre-fabrication

- Document professionally, traceable and editable

- Easier implementation and documentation of changes

- Easy access to professional documentation for management, operation and maintenance (FDV)

Typical Delivery:

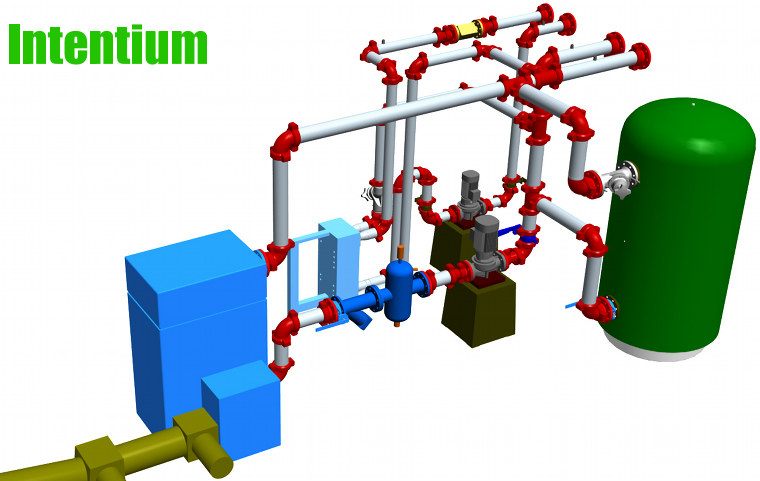

3D model of the plant (see image example in jpg format)Production documents, 2D drawings (download example in pdf format)

Detailed bill of materials (download example in excel format)

Additional services:

Obtaining quotes for materials, equipment and productionOrdering and control of delivery of materials and equipment

Support for the production

Additional documents for management, operation and maintenance (FDV)

Why Intentium?

- We use the high-end 3D CAD tool Pro/Engineer, which can handle large assemblies better than the more typical mid-range tools like SolidWorks and Inventor (though we also have extensive experience with CAD tools like, SolidWorks, Solid Edge, Catia, I-Deas and more).

- We have the engineering knowledge in energy, process and manufacturing plants - and talks easily with specialists in many disciplines.

- We work fast, efficiently and accurately. For example, we find standard components either swiftly in one of several Internet component libraries (eg. www.solidcomponents.com), design the model quickly, or find this already in our large database.

- We try to find solutions, rather than write change notifications.